Oil & Gas

Infiswift Technologies helps Oil and Gas companies extensively in various parts of their operation, whether it’s upstream, midstream or downstream through our industry-leading Infiswift IoT+AI Fabric. We can help all the way from digital transformation of your infrastructure and operations to building advanced AI-driven applications to solve the most complex challenges in your operations or business.

Case Study

Oilfield Services companies or OEMs need to be able to collect the data from their customers in order to use machine learning and AI to benefit their customers. One of the major challenges in Oil and Gas industry is data privacy. Most production customers do not want to share their sensitive production data even with the Oilfield Services company or OEMs whose equipment they use in a downhole environment. How could Oilfield Services companies or OEMs deploy machine learning models or improve the machine learning models of their customers if they don’t have access to data? This is an actual problem for one of Infiswift’s customers who is an OEM which manufactures downhole equipment.

Infiswift’s IoT+AI Fabric unique deployment flexibility—which allows it to run entirely in any customer’s on-prem environment—offers an elegant solution to the development and deployment of such AI-driven applications despite the restrictive environment.

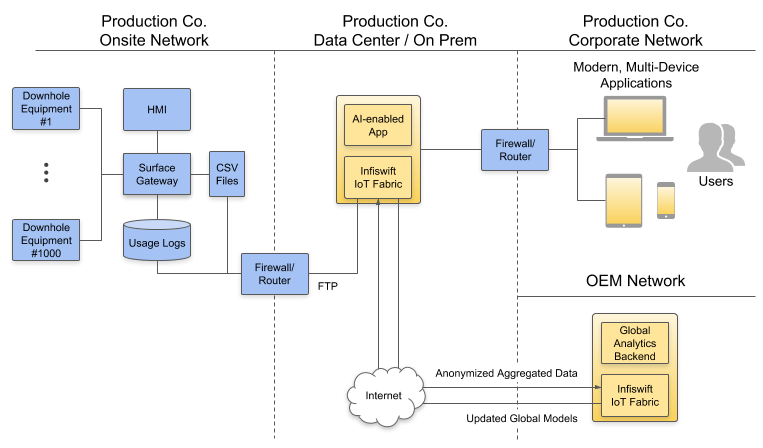

Infiswift’s solution for this OEM customer is expressed in the above architecture diagram. The Customer referred to in this diagram is the OEM which manufactures downhole equipment. The production company deploys the downhole equipment in its wells and collects production data. The production company does not wish to share any raw data, but will share aggregated data in an anonymized format, excluding some sensitive data like pressure. Infiswift IoT+AI Fabric is deployed fully on-premise in the production company’s on-prem data center. This deployment option allows all sensitive data to be fully utilized locally and machine learning models be trained locally in a customized manner to just all wells of the production company without the data every leaving the production company’s network.

In addition to the ability to run machine learning locally, there is also a need for Infiswift’s Customer (the OEM company) to collect the allowed data from the production company in anonymized aggregated format. To enable this, Infiswift IoT+AI Fabric has a ‘sync’ mode by which it can synchronize the allowed aggregated and anonymized data with the OEM (Infiswift’s Customer). This aggregated data from each production company is used to train the global machine learning models which are common across all customers of the OEM. These global models are then periodically redistributed back to the individual production companies to improve their models from the learnings from other customers of OEM.

- The tool OEM is able to collect high quality lifecycle data about their product.

- The tool users and oilfield services customers get high value services and feedback, all while maintaining confidence in their sensitive data never leaving their control.

- Both companies are able to collaborate more effectively through reduced administration and integration costs.